Category : Case Studies, News by T-Pole | Reliability | 18 June 2025

A user turns on their computer and the touchscreen simply doesn’t respond. They restart the system and, as if by magic, everything works again. A sporadic episode? Perhaps. But for those who manufacture and assemble industrial machines, this “sometimes it doesn’t work” is an alarm bell signalling a latent problem, a potential source of frustration for the customer, and a risk to the product’s reliability.

This seemingly trivial scenario is actually a classic example of a complex problem that needs to be thoroughly investigated. It’s not about a broken component, but an instability, a lack of perfect harmony within the computer’s hardware and software ecosystem.

Typically, the cause lies in a non-optimal “fine-tuning” of the BIOS/UEFI or the touchscreen controller’s firmware. Booting up a computer, a mundane operation we’ve done thousands of times, is actually a very rapid and complex sequence of operations: the BIOS/UEFI must initialize the hardware, check the peripherals, and hand over control to the operating system. In these few seconds, imperfect timing, suboptimal power management of the USB ports, or a low-level incompatibility between the controller’s firmware and the motherboard can prevent a proper “handshake”—the digital agreement that allows the touchscreen to be recognized.

Beyond functional testing: the need for stress testing

So, how can you ensure a system is truly reliable? A simple functional test of a few minutes is completely insufficient. Verifying that the touchscreen works once in the lab provides no guarantee that it will work on the hundredth startup at the customer’s home or in the factory where it will be used for years.

It, therefore, becomes crucial to adopt a structured methodology to detect these potential malfunctions, especially during the homologation phase of a new product or configuration. At TPole, we dedicate meticulous attention to this type of verification because we know that reliability is built on details.

To uncover problems of this nature, the strategy must be twofold: intensity and analysis.

- Simultaneous and automated stress testing: instead of testing one unit at a time, multiple systems are put under stress in parallel. Using specific software and hardware, these units are subjected to hundreds or thousands of power-on, power-off, and restart cycles. Automation is key: it allows for months of potential use to be compressed into a few days of testing, maximizing the chances that the sporadic defect will manifest.

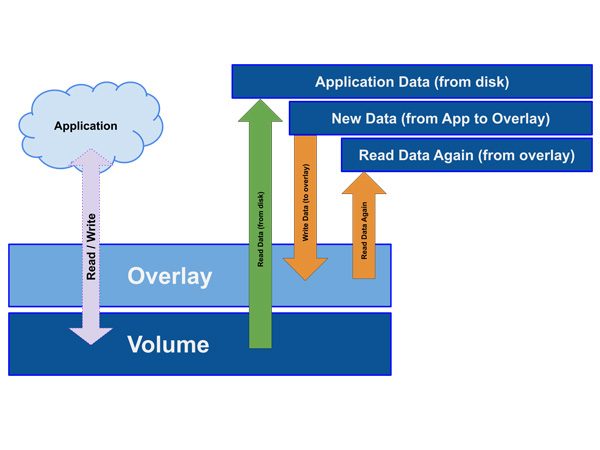

- Centralized logging and data analysis: “stressing” the systems is only half the job. Every single action and its result must be meticulously tracked. This is where an advanced logging system comes into play. At each startup, dedicated software records the status of all peripherals, including the presence (or absence) of the touchscreen controller in the operating system. All this data, from all the machines under test, is sent to a centralized server.

This approach transforms anecdotes (“sometimes it doesn’t work”) into statistical data which can be tracked and analysed. By analysing the logs, our engineers can correlate failures with specific events: do they occur more often during a cold boot? After a warm restart? On a particular motherboard revision? This wealth of data is the only way to identify the hidden pattern behind a seemingly random problem.

Once the problem is isolated, we can intervene with informed action, working closely with motherboard or controller manufacturers to perform the necessary “fine-tuning”: modifying a BIOS setting, requesting an updated firmware version, or, in more complex cases, intervening in the hardware design.

A customer’s trust is earned not only with top performance but, above all, with the certainty that the product will work, always. It is a silent, taken-for-granted reliability, but one that is born from a rigorous, methodical, and uncompromising validation process. It is the commitment to never consider a “sporadic” issue a minor problem, but as an opportunity to make the final product even more robust and reliable.

For more details on the type of stress testing we can offer to improve the reliability of your products, contact us today through our contact page.