Category : Case Studies, News by T-Pole, Services | cooling, Reliability, remote access, Thermal Tests | 29 April 2025

Introduction

Many of our customers operate in sectors where reliability is everything; electronic measurement and control systems must operate without failure even in the most extreme environmental conditions. Ensuring that an industrial computer, perhaps integrated into a custom enclosure, meets its operating specifications, especially regarding temperature, becomes a crucial step. This case study illustrates how a targeted thermal testing service provided the necessary guarantees to ensure the long-term success of a mission-critical application.

The customer’s challenge: a custom system for the geological sector

One of our customers, active in the field of geology, had developed a critical application based on an industrial computer. The particularity lay in the need to integrate the motherboard and several add-on boards within a custom box with an IP67 protection rating. This system was equipped with essential functionalities for the application:

- LTE connectivity (via SIM card) for data communication.

- GPS for precise geolocation.

- CAN bus interface for direct connection to the control unit of the machine on which it would be installed.

Given the “mission-critical” nature of the application and the potentially extreme operating environment, the customer could not settle for simple theoretical specifications. They needed concrete guarantees on the maximum operating temperature the complete system could reach inside the IP67 box, ensuring it remained within safe limits for all components.

The TPole solution: rigorous and collaborative thermal testing

To meet this fundamental need, we offered and implemented a complete thermal validation process:

- Definition of test specifications: Together with the customer, we established a detailed test protocol to be executed in a climatic chamber, simulating the most demanding operating conditions.

- Setup and monitoring: The complete system (IP67 box with motherboard and add-ons) was placed inside the climatic chamber. Certified thermal probes were strategically positioned at critical points inside the box to precisely measure the temperatures reached.

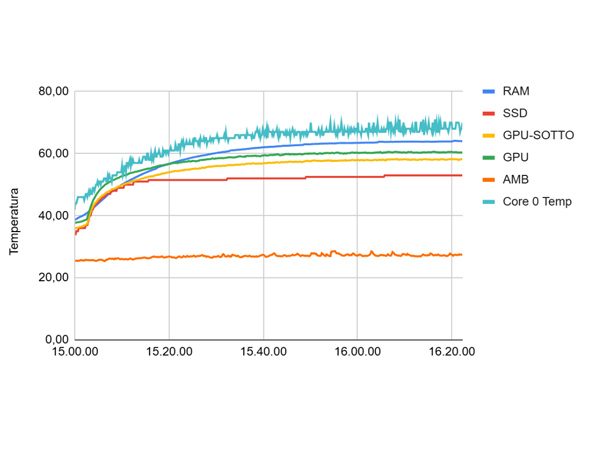

- Interactive and realistic testing: During the execution of the thermal tests, the customer had the possibility to connect remotely directly to the system under test. This allowed them to load their application software and stress the system realistically, simulating the actual workload in the field. Simultaneously, they could monitor the data from the thermal probes in real-time, verifying the trend of internal temperatures.

- Comprehensive reporting: At the end of the testing procedure, we provided the customer with an exhaustive report. The document included not only the numerical results but also detailed graphs showing the evolution of temperatures over time for each probe positioned inside the box.

The result: proven reliability in the field

The tests provided the customer with the assurance they sought: the custom solution operated reliably within the specified thermal limits, even under load and in difficult simulated environmental conditions. The definitive proof of success came from the field: to date, approximately 150 units of these systems have been installed and have been working in extreme operating conditions for over five years. The customer expressed extreme satisfaction with the performance and reliability demonstrated by the solution, validated thanks to the rigorous preliminary thermal tests.

Conclusion

This case study demonstrates the crucial importance of environmental tests, particularly thermal ones, when integrating electronic components into custom solutions, especially for mission-critical applications. Using an industrial computer in full compliance with its specifications, even within a non-standard enclosure, requires accurate validation. Providing detailed reports and graphs based on certified measurements offers customer the peace of mind and guarantee necessary to implement their solutions even in the most challenging environments, ensuring reliable and lasting performance over time.

To find out how to best leverage TPole’s experience to optimize your products, contact us today through our contact page.