Category : Hardware News, News by T-Pole | Bespoke, HDMI, HMI, remote access | 25 June 2025

In the field of industrial automation, the distance between the control computer and the operator panel often presents a technical and economic challenge. Extending video and USB signals over long distances can become a nightmare due to interference, signal degradation, and the prohibitive costs of special cables.

At TPole, we have developed an elegant and powerful solution to overcome this obstacle: an industrial monitor that connects to the PC using a single network cable, extending the video, touch, and USB signals up to 100 meters away.

The problem: video cables and interference

Anyone who works with industrial machinery knows the problem. Digital video signals (HDMI, DisplayPort, DVI) and older analog signals are extremely sensitive to distance and electromagnetic interference, which is very common in production environments. To extend beyond a few meters, very high-quality cables are required, which are expensive and often bulky, without always guaranteeing a stable and reliable result.

The solution: video and data over Ethernet

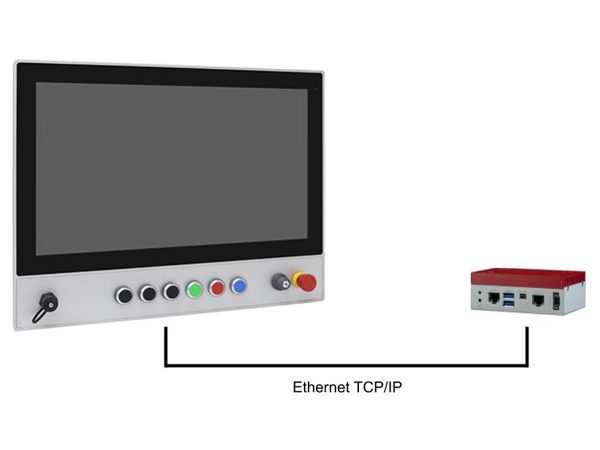

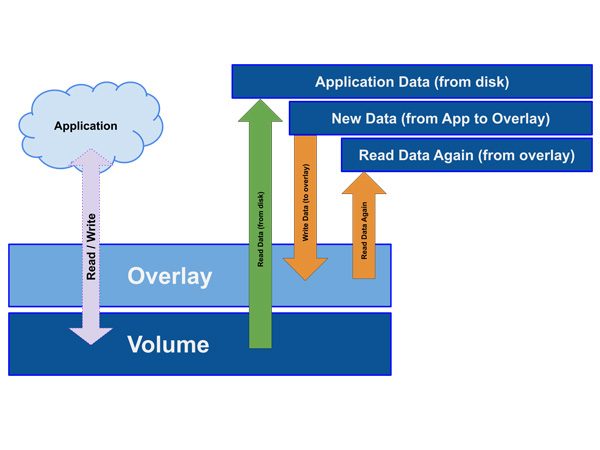

Our solution offers an innovative and advantageous approach compared to traditional technology. We have integrated a remoting board directly inside an industrial monitor. This allows the video signal to be transmitted directly over the Ethernet network.

How does it work? It’s surprisingly simple:

- Computer side: all that’s needed is a free Ethernet port and the installation of dedicated software. This allows any computer to be used without the need for specific hardware.

- Connection: a single standard network cable connects the PC to the monitor, up to 100 meters away.

- Monitor side: the monitor receives the video signal and displays it. The USB signal also travels over the same cable, instantly enabling the touchscreen functionality without the need for additional wiring.

As seen in the photo, the only connection between the PC and the monitor is the Ethernet cable. This eliminates the need for expensive video and USB cables, simplifying installation and ensuring a clean, stable signal.

Maximum flexibility and customization

This technology not only solves the distance problem but also opens up a world of new possibilities:

Integration of other peripherals

For a specific project, we enhanced the solution by integrating an RFID reader and a smart card reader directly into the monitor. This allows for the implementation of secure operator identification systems directly at the workstation, without the need for external devices.

Physical modularity

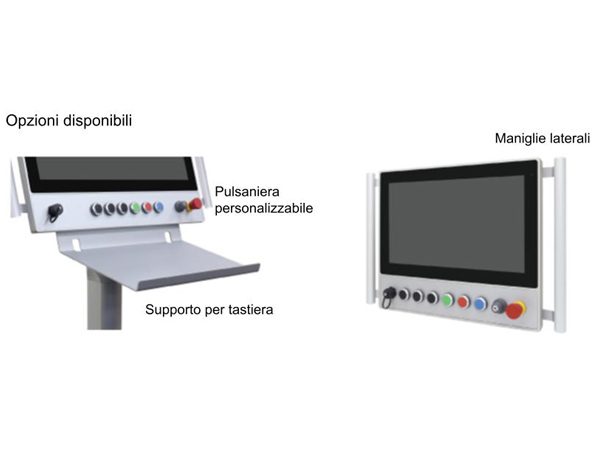

The monitor is designed to be customized. A wide range of elements can be mounted on the central part of the frame according to customer specifications, such as buttons, selectors, and emergency buttons, creating a complete and integrated control console.

Key advantages at a glance

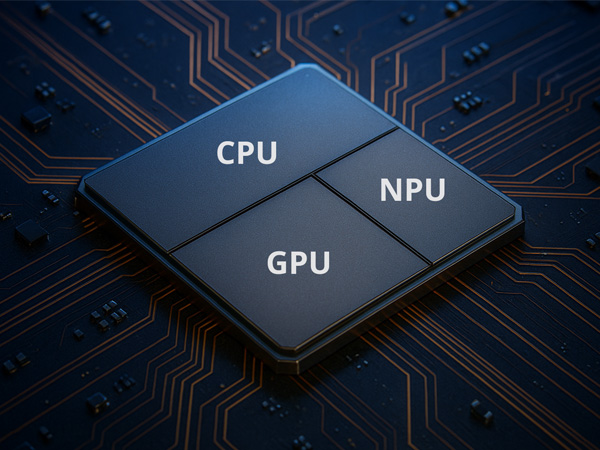

- Unlimited computing power: frees you from the need to use panel PCs, which are often limited in performance. It is now possible to connect monitors to powerful desktop machines or industrial servers, while keeping them safe in dedicated cabinets.

- Signal stability: eliminates flicker, signal loss, and interference issues typical of long HDMI, DP, or DVI cables.

- Scalability: it is possible to connect multiple remote monitors to a single PC, each with its own network cable, to manage multiple workstations with a single computing unit.

- Simplicity and savings: a single standard network cable for video, touch, and USB peripherals drastically reduces the costs of cabling, installation, and maintenance.

This solution represents the definitive answer for anyone looking for a reliable, flexible, and cost-effective way to remote Human-Machine Interfaces (HMIs) in complex industrial environments.