Category : Case Studies, Hardware News, News by T-Pole | GPIO | 13 August 2025

Industrial computers are the brains behind countless automation applications, but their computing power must be able to translate into concrete actions in the physical world. Whether it’s turning on a light, activating a relay, communicating with a PLC, or reading the status of a photocell, the I/O (Input/Output) interface is a crucial element.

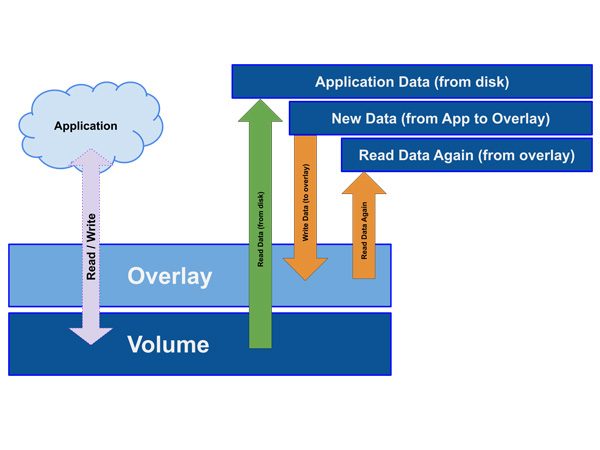

Almost every industrial motherboard is equipped with GPIO (General Purpose I/O) pins, but this is often where the problem arises: these I/Os are designed for low voltage and low current logic signals (e.g., 3.3V or 5V), which are completely inadequate for the robust environment of an electrical cabinet, which typically operates at 12V or 24V.

The problem: native GPIO and interfacing complexity

The system integrator faces a challenge: how to safely and reliably connect these weak GPIO signals to industrial devices? The most common solution is to use external expansion modules, connected via PCIe, USB, serial, or Ethernet buses. Although functional, these modules introduce several disadvantages:

- Increased Costs: Each additional module represents an extra expense.

- Software Complexity: They require the installation of specific drivers and the integration of new software libraries, deviating from the stock software provided by the motherboard manufacturer.

- Reliability: They add a potential point of failure to the system.

- NPN / PNP Management: Often, configuring inputs and outputs according to NPN or PNP standards remains a cumbersome operation.

The TPole solution: enhancing existing hardware

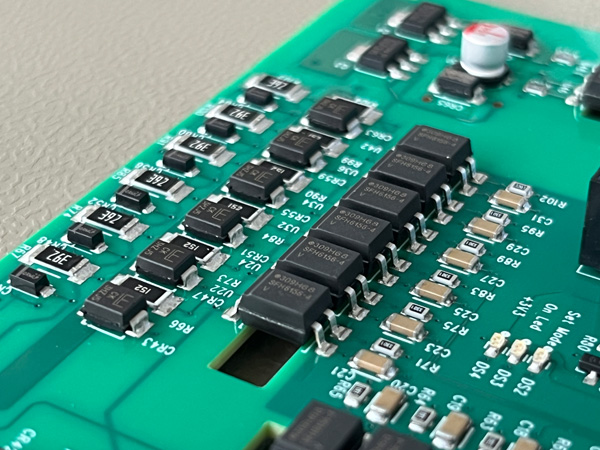

At TPole, we believe in optimizing existing resources. Instead of adding external components, we have developed a smarter solution: a signal conditioning electronic board. This board, available in standard versions or custom-designed to meet the client’s needs, acts as a “translator” and “amplifier” between the motherboard’s GPIOs and the field. It allows you to:

- Use native GPIOs to drive industrial loads such as relays, lights, or contactors.

- Read signals from 24V sensors, photocells, and switches.

- Easily manage NPN and PNP configurations, making the system flexible and compatible with any device.

In practice, thanks to our experience, we enable the hardware already present on your PC to communicate directly with the industrial environment, without the need to purchase expensive additional modules.

Long-term advantages: stability and security for the future

Choosing this solution is not just a matter of immediate savings. It offers crucial strategic advantages for the life cycle of an industrial product.

Our solution is inextricably linked to the motherboard. This means that the I/O function will have the same lifespan as the board itself, ensuring stability and the certainty of being able to find identical spare parts for years. Furthermore, the software interface does not change, as you continue to use the firmware and drivers provided by the board manufacturer.

This approach also proves to be a winning strategy for the future. Motherboard manufacturers tend to maintain strong firmware compatibility between successive generations of the same product. Consequently, when the time comes to update the hardware, porting the client’s software will be extremely simple and fast, preserving the investment made in development. With TPole, you not only solve a technical problem, but you adopt a strategy that guarantees efficiency, savings, and operational continuity over time.